Note: This is an excerpt from Life Cycle Assessment of Buildings: A Practice Guide.

How do buildings impact the environment?

Constructing a building and using it for many years produces long-lasting impacts on human health and the environment. Life cycle assessment (LCA) is the rapidly evolving science of illuminating these impacts in terms of their quality, severity, and duration.

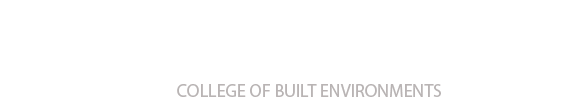

A building generates environmental impacts throughout its life cycle. The various stages of a typical life cycle as defined in LCA are:

- A: the production and construction stages,

- B: the use stage,

- C: the end-of-life stage, and

- D: externalized impacts beyond the system boundary.

The production stage involves the energy and resources used to extract raw materials, to transport the materials to product manufacturing facilities, and to produce the final building products. The construction stage involves the transportation of materials to the construction site as well as the energy used to power the construction equipment, to supply supporting construction materials, and to dispose of any waste generated during the construction process. The use stage involves the impacts of occupying a building over its lifetime due to lighting, heating, water use, and any materials used for maintenance, repairs, and replacement. The end-of-life stage involves the demolition and disposal of the building as well as waste processing (if the building is not repurposed or improved for further occupancy or use). Finally, the last stage gathers all of the miscellaneous effects of reusing, recycling, and/or recovering materials, energy, or water from the project. These effects are called externalized impacts because they are manifested outside of the system boundary, which is defined as the physical limits of the LCA study.

Throughout the life cycle stages of a building, emissions and other pollutants are produced and released into the surrounding environment. A visual depiction of where these emissions may occur during a building’s life cycle is shown in Figure 1.

Figure 1. Sources of emissions by life cycle stage (A, B, C, D) of a building based on stage definitions from European Standard (EN) 15978 (credit: Meghan Lewis).

Cradle? Gate? Grave?

The beginning of the life cycle is also referred to as the “cradle,” while the exit point of the manufacturing facilities is known as the “gate,” and the end of the life cycle is known as the “grave.” Thus, terms such as “cradle-to-gate” and “cradle-to-grave” are used to refer to different ranges of the life cycle.

The many names of “carbon”

The following is a list of terms that are often used somewhat interchangeably to refer to the emissions associated with climate change or global warming [1]:

- Carbon

- Carbon footprint

- Carbon dioxide (CO2)

- Carbon dioxide equivalent (CO2e or CO2eq)

- Greenhouse gas (GHG) emissions

- Fossil fuel emissions

- Global warming potential (GWP)

- Climate change (CC) potential

These terms do not share the exact same meaning. Even though the term “carbon” is commonly associated with climate change, it is technically not elemental carbon that contributes to climate change, but carbon dioxide gas along with many other substances such as nitrous oxide and methane. Nevertheless, “carbon” is often used as an abbreviation to refer to global warming potential.

What are emissions and why do they matter?

LCA tracks emissions, which are substances released into the air, water, or soil. Emissions and other pollutants can adversely affect the environment and human health in a variety of ways. Of key importance are greenhouse gas (GHG) emissions, which contribute to the disruption of the global climate. Climate change is projected to undermine food and water security, but ongoing effects are already devastating, especially for those who are geographically or economically vulnerable to droughts, flooding, and other natural disasters.

The continued use of fossil fuels is of particular concern in the modern age. The built environment is sustained directly and indirectly by the combustion of fossil fuels and accounts for nearly half of the energy produced in the United States through the construction, operation, and demolition of buildings. Given the building industry’s enormous global footprint, industry professionals stand in a critical position to cease causing – and start healing – the warming climate.

How are emissions translated into environmental impacts?

Emissions associated with materials and products are typically estimated from computational models or are based on actual measurements. Emissions are translated into environmental impacts by multiplying their masses with characterization factors. LCA assesses a number of environmental impact categories, which are broad measures of environmental change, encompassing the effects of many types of emissions. The five most prominent environmental impact categories used in US green building initiatives and LCA tools are as follows:

- Global warming potential: Describes potential changes in local, regional, or global surface temperatures caused by an increased concentration of GHGs in the atmosphere, which traps heat from solar radiation through the “greenhouse effect.” This impact category is strongly correlated with two others – acidification and smog formation – because global warming is largely driven by the burning of fossil fuels, which also directly contributes to these two impact categories.

- Acidification potential: Describes the acidifying effect of substances in water and soil. Acidification can occur when substances such as carbon dioxide dissolve in water and lower the pH levels, increasing the acidity of the water. In LCA, this terms refers to the local effects of acidification. However, on a global level, ocean acidification threatens the survival of certain species and jeopardizes marine food supplies for humans. Additional potential effects of acidification include the destruction of forests and erosion of building materials.

- Eutrophication potential: Describes the effect of adding nutrients to soil or water, causing certain species to dominate an ecosystem and compromise the survival of other species. An example of this is when an overgrowth of algae depletes water oxygen levels and kills off fish. Fertilizers are a dominant of eutrophication.

- Ozone depletion potential: Describes the degrading effect of substances in the stratosphere on the ozone layer, weakening the ozone layer’s ability to prevent excessive ultraviolet radiation from reaching Earth’s surface. The Montreal Protocol has effectively mobilized global engagement to address this issue. Ozone impacts from building materials are rarely significant, but refrigerants used in mechanical systems are an area of concern.

- Smog formation potential: Describes the presence of substances such as carbon monoxide and volatile organic compounds (VOCs) in the atmosphere, forming photochemical smog. Smog is harmful to human health (e.g. causing respiratory issues) and ecosystems (e.g. causing deterioration of crops).

In the US, the EPA has published characterization factors in the Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI). Other characterization factors are used in other regions. Databases known as life cycle inventories (LCIs) report these emissions for different processes that contribute to the creation of a material or product. Different LCIs reflect differences in regional practices and manufacturing processes.

Carbon:

embodied and operational

LCA can assess many environmental impacts, but GWP is often the focus of LCA studies. Embodied carbon commonly refers to the GWP attributed to materials and energy used in the construction and maintenance of buildings. Operating carbon refers to the GWP attributed to operation and use of the building.

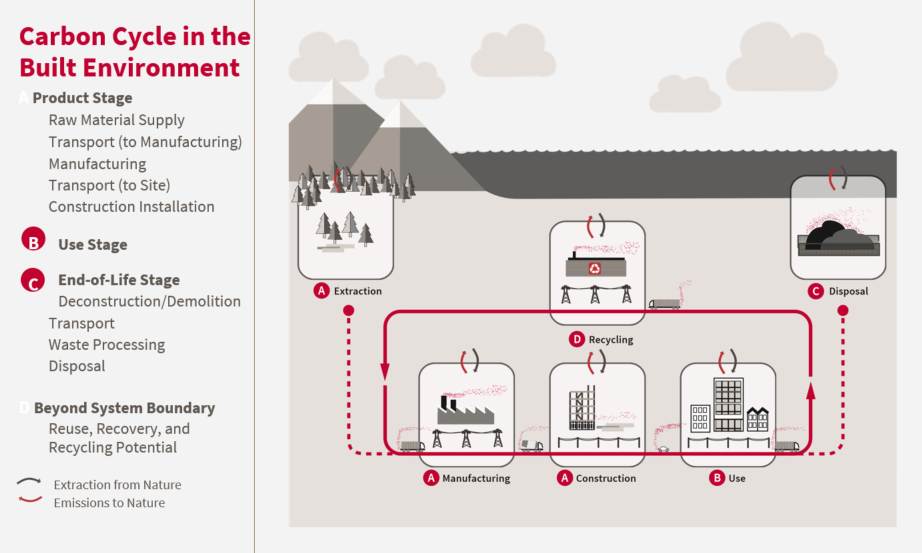

In an LCA of a building, all of the material and process quantities are gathered into a body of information known as the inventory and multiplied with the appropriate impacts for each material or process. The overall results are summed to obtain the overall environmental impacts of a building. A simple example of the calculation process is shown in Figure 2.

How is LCA used in the building industry?

In the building industry, LCA is commonly used to:

- Help building owners make informed choices regarding sustainability and/ or resilience

- Evaluate design options by providing insight into materials choices and their environmental impacts

- Achieve green building certification (e.g. in LEED v4 or Living Building Challenge)

- Assist in assessing the environmental benefits of new products and/or policy

- State that a system or product is environmentally preferable to another (to make a comparative assertion)

- Compare to benchmarks to evaluate a building’s performance

The results of an LCA can illuminate which parts of a building have particularly high environmental impacts. This type of hot-spot analysis can help the design team achieve a more environmentally conscious design. However, any design modification should be evaluated with another round of LCA. For example, changing the structural material of a building from concrete to steel would affect the insulation design due to the differing thermal properties of concrete and steel. The insulation components would then have to be redesigned before the LCA is performed again.

Figure 2. Simple example of LCA calculation process.

In design practice, LCA can be used as a comparative model aimed at making incremental improvements and evaluating design options. Simply put, LCA helps designers evaluate the environmental consequences of different designs by comparing buildings, materials, or assemblies.

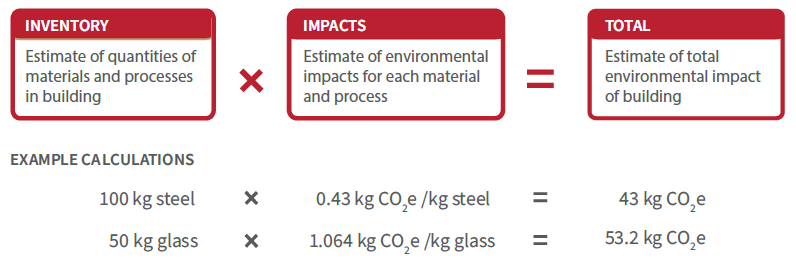

This iterative process of LCA is expanded upon in the second part of the Practice Guide: Implementation. A preview of the steps for conducting an LCA is shown in Figure 3, which illustrates the iterative process of LCA. The dashed lines indicate the potential paths of iteration through the LCA process.

Figure 3. Simple diagram of LCA process.

What is a benchmark?

A benchmark is “a set of environmental impact results that serve as a reference point from which the relative performance of other buildings can be evaluated”. Benchmarks for operational energy efficiency are measured using energy use intensity (EUI). Efforts to develop building-level LCA benchmarks are under way in North America [8], [9], and are more advanced in Europe.